Sensors

-Throttle Position Sensor (TPS)

The TPS that I used in this experiment is a, Toyota 89452 - 22090 Denso.

The internal workings of this TPS is as follows, As the accelerator pedal is pushed the throttle plate opens, rotating the sensors internal variable resistor. As the throttle opens, voltage returned to the computer from the throttle position sensor varies, (normally increasing), signalling the rate of throttle opening as well as throttle position. The computer uses this information to adjust fuel trim, which is the amount of time the injectors are open, delivering more fuel.

The TPS will now be connected to a 5V power supply so that the voltage output can be tested at different voltages.

Throttle Angle (°C) Voltage Output (V)

0 0.549

10 1

22.5 2.08

45 2.40

67.5 3.31

90 3.92

Throttle Position Switch (TPS)

If the Throttle Position Switch seems to be a possibility for your vehicle not running correctly then the condition of the contacts inside the switch is the first test, and should be checked for high resistance in both idle and full throttle position. To do this on a 3 pin TPS, place your earth ohmmeter lead onto the earth pin of the TPS and your positive lead onto either the IDL (Idle Circuit) pin, followed by the PSW (Power Switch), also known as WOT (Wide Open Throttle), whilst keeping your earth lead on the E (Earth) pin.

My results at both PSW and IDL pins were 0.6Ω showing continuity. This result is what you would expect to find on a working TPS.

At PSW -WOT= 0Ω At IDLE - Idle= 0Ω

-Idle= OL - WOT= OL

The results above indicate to me that at Idle, Idle is 0Ω and at PSW, WOT is 0Ω resulting in 0Ω meaning on and OL meaning off.

The Throttle Position Switch is operated by the throttle. In early L-Jetronic systems the TPS has a set of contacts for idle and full throttle positions. When checking the TPS with an ohmmeter, readings of 0.6Ω or close to it shows continuity at each point. The resistance between idle and WOT varies depending on the car, the switch then signals the throttle opening to the ECU which then provides mixture corrections for both idle, off-idle and full throttle conditions.

Manifold Absolute Pressure (MAP)

I am to wire up a 3 pin MAP sensor with a 5V feed and earth. After correct connection assembly of the MAP sensor is done then I will measure the return voltage from the third wire, whilst applying increasing vacuum to the MAP sensor.

Vacuum (Hg) Voltage (V)

0 3.08

5 2.93

10 2.46

15 1.98

20 1.5

25 1

30 0.625

The MAP sensor readings show that it is good.

The Map sensor reads pressure not vacuum.

The MAP sensor works as follows, the control unit will provide the MAP sensor with a sensor reference voltage and a sensor ground. A signal is sent back to the ECU as a result of the internal MAP sensor circuit being strained by the manifold vacuum strength. The output changes along with changes in vacuum. This is because the silicon chip inside the MAP sensor changes its resistance with the changes in pressure. This change in resistance alters the voltage signal. The ECM (Electronic Control Module) interprets the voltage signal as pressure and any change in the voltage signal means their was a change in pressure. As vacuum in the engine increases, the voltage output will decrease.

After correctly wiring up the MAF sensor and without passing any air over the sensor the initial powered up voltage that I recorded was 1.084V.

As I passed air over the sensor the voltage increased, dependant on the amount of air passing through it.

From the result above I can tell the MAF sensor is working correctly.

The MAF sensor or Hotwire sensor measures incoming air by mass (kg/s). Early MAF sensors sample all incoming air through a cylindrical housing. The incoming air passes over a thin arrangement of durable tungsten wire which is heated to a constant 100°C above the ambient air temperature. The intake air flow has a cooling affect on the MAF sensor. The more air that flows, the more current that is fed by the air mass meter circuit to keep the wire at the pre-set constant temperature of 120°C. This arrangement change is converted to a varying voltage or frequency and signalled to the ECU as a measure of engine load (relative airflow).

Vane/Flap Air Flow Sensor

After correctly wiring up the Vane/Flap Air Flow sensor I was asked to measure the voltage output at different vane angles, my results were as followed.

Vane Angle Voltage Output

Closed 4.5

1/4 Open 2.6

2/4 Open 2

3/4 Open 1.6

WOT 1.5

Vane Air Flow Meter from the data collected shows that is it functioning correctly by following the basic principle of, as more air passes through the AFM, the lower the voltage reading.

Vane/Flap Air Flow sensor is a device that measures how much air is flowing through a tube. It measures the air volume currently inside of it. The voltage in the AFMAFM.

Coolant Temperature Sensor (CTS)

To test this sensor it is to be suspended in a container of water with a constant increase of temperature until around 100°C and record your findings.

Manufacture Specifications:

Temperature (°C) Resistance (Ω)

20 2000-3000

50 700-1000

80 200-400

85+ less than 200

My results:

Temperature (°C) Resistance (Ω)

20 2000

30 1600

40 833

50 655 60 563

70 421

80 306

90 187

Yes this CTS is within manufacture Specs provided.

Temperature (°C) Resistance (Ω)

20 2000-3000

50 700-1000

80 200-400

85+ less than 200

This CTS is a Negative Temperature Co-Efficient Thermistor

The variable resistor type of coolant sensors which I have used are smarter than the on/off switch type because they provide the PCM with a more accurate indication of actual engine temperature. The PCM feeds the sensor a fixed reference voltage of usually 5 volts when the engine is on. The resistance in the sensor is high when cold, and drops as the sensor warms up to alter the return voltage signal back up to the PCM. The PCM uses this changing voltage to determine the engine temperature.

Thermo Fan Switch

As the temperature increases the resistance decreases as it is supposed to. This leads me to believe that this sensor is working correctly.

Yes the Thermo Fan Switch is a thermistor because the resistance varies with temperature change.

Early cars without air conditioning were equipped with a single radiator cooling fan, as opposed to two fans. The single cooling fan is supplied by a parallel circuit. Like the cars with air conditioning, if a high coolant temperature exists with the ignition off, the contact in the Thermo Fan Switch closes and causes the cooling fan too run in slow speed (via the resistor in the parallel circuit). When the ignition is turned on the cooling fan relay is energized, closing a contact to short out the slow speed resistor. If the high temperature condition still exists, (I.E. the thermo fan switch is closed), the cooling fan will run in fast speed. The resistance should read less than 1Ω. If the fan will not run in slow speed, an infinite/overload (OL) reading is seen.

Intake Air Temperature Sensor (IAT)

I was to connect the IAT sensor terminals to an ohmmeter and suspend the sensor in a container. The water was then to be heated up to 95°C and the water temperature checked with a thermometer. I noted the resistance changes related to changes in temperature °C.

Temperature (°C) Resistance (Ω)

20 2700

40 1890

50 932

70 466

80 356

95 214

Temperature increases and resistance decreases, this sensor is working right.

The IAT sensor is a negative temperature co-efficient thermistor.

My results from the air temperature sensor and the engine coolant temperature sensor tells me that these sensors are both negative temperature co-efficient thermistors. This is shown by the same experiment being tested upon both sensors. As the temperature increases, resistance decreases. This information is sent again to the PCM through means of a 5V reference wire. The resistance in the sensor is high when cold but drops as the sensor warms up to alter the return voltage signal back to the PCM. The PCM uses this changing voltage to determine the engine temperature.

Knock Sensor

This waveform was not recorded in-class. It was taken off google images because the oscilloscope used in-class was not able to capture a waveform due to the small voltage it put out and the oscilloscope's voltage per division not being able to go low enough.

The knock sensor is designed to allow the engine to run at the most advanced timing possible without detonating. As soon as detonation, or pinking, occurs the knock sensor sends a voltage to the ECU, telling it to retard the timing in order to stop detonation from occurring, the timing is then slowly advanced constantly until detonation happens again and the knock sensor does its thing. This system allows the car to run at optimum efficiency. The voltage you see from the knock sensor without any voltage being supplied to it is from the knock sensor having peizo-electric crystals.

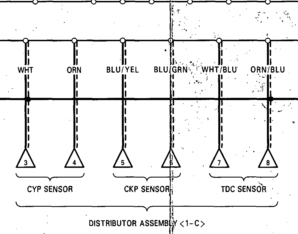

Optical Distributor

The Optical Distributor has 37.7mV through it whilst it is not moving. It has less voltage the faster it rotates, resulting in the very low reading at it whilst it is not moving. A faster rotation then means more frequency and a faster switching time. The amplitude (Volt) will stay the same.

On the waveform above, you can see that the Optical Distributor begins on. Next one of the four blades on the (Chopper Plate) will interrupt the signal in the photo electric shell, switching it off. This switching happens faster as the car is under higher load driving conditions.

In all of the speed sensors above , the degrees turned of the distributor is always half the speed of the crankshaft. For example, a 360° (1 rotation) of the distributor will result in a 720° or 2 rotations of the crankshaft.

Injector Testing

Checking injectors off a vehicle.

Only two injectors were available for testing.

Injector Number 1 2

Manufacturer Specs (Ω) 14-17 14-17

Winding Resistance (Ω) 15.5 14

Earth Leakage Test OL OL

Next I wired up my injectors to a power supply in order to hear an audible clicking sound, telling me that the injectors are working. Both injectors tested were clicking, resulting in them being functional.

Other engine problems which could give the same result as an injector not firing could be:

- Damaged coil

- Faulty spark plug

- Faulty HT lead

Cleaning Injectors off a Vehicle

When removing fuel injectors from the engine, take care to not damage the plugs or create an electrical fault.

The injectors had no leakage, I.E. 0 drips per minute.

The injector flow rate I recorded was 45cc per minute.

Only one injector needed attention which was injector 4, this is only because the plug on the injector is faulty, resulting in a poor electrical collection.

Testing Ignition Coils

Ignition Coil 1:

Part Number: 16C6

Coil Voltage: 6V

Primary Winding Resistance Measured: 2.1Ω

Secondary Winding Resistance Measured: 7.5KΩ

Earth Leakage Test: OL

Ignition Coil 2:

Part Number: F-088

Coil Voltage: 12V

Primary Winding Resistance Measured: 0.9Ω

Secondary Winding Resistance Measured: 12.57KΩ

Earth Leakage Test: OL

Wasted Spark Coil Pack:

Coil Secondary 1: 12.2KΩ

Coil Secondary 2: 12.3KΩ

Coil Secondary 3: 12.3KΩ

Coil Primary 1: 0.7Ω

Coil Primary 2: 0.8Ω

Coil Primary 3: 0.6Ω

Testing Ballast Resistors

Part Number: BR1

Ohm Spec: 1.2Ω

Measured Ohm: 1.2Ω

Standard Single Tower Coil

I was asked to:

- Wire up a ballast resistor in series with my coil primary winding values as shown in the diagram below

- Connect an ammeter in series and note the current draw

- Measure and note the voltage drop across the ballast resistor

- Measure and note the voltage drop across the coil primary

Current Draw: 3.1A

Coil Calculated Voltage Drop: 6.51V

Coil Measured Voltage Drop: 10.6V

Ballast Resistor Calculated Voltage Drop: 3.72V

Ballast Resistor Measured Voltage Drop: 1.3V

My calculated values did not exactly measure our recorded results because the power supply we were using could only provide us with 3A were as if a power supply that could draw more amps were used, a more accurate result would have been measured.

Wiring Up Ignition Systems

Wire up an ignition module using a function generator to trigger the module. Have a coil and spark plug in the circuit so the spark plug can fire. Draw a wiring diagram of how I wired the circuit.

Wire up an ignition module using a distributor to trigger the module. Have a coil and a spark plug in the circuit so the spark plug can fire. Draw a wiring diagram of how I wired the circuit.

Wire up the Wasted Spark ignition system using the function generator to trigger the modules. Have the coils and spark plugs in the circuit so the spark plugs can fire. Draw a wiring diagram of how I wired the circuit.

Wire up the Coil Over ignition system using the function generator to trigger the module. Have the coil and spark plug in the circuit so the spark plug can fire. Draw a wiring diagram of how I wired the circuit.

Building A Simplified Ignition Module

Build the ignition circuit shown below using two BC547 transistors.

The max current value of the BC547 transistors is 100mA. The resistance of the coil is found using the formula: R=V/I

=12/0.1

=120Ω so a 100R resistor will be used.

Difficulties encountered whilst making this circuit were:

- Transistors used were too small i.e. current rating was too low.

- Resistor of 100Ω was too big, no resistor was actually needed at R3.

If I were going to build this circuit again I would:

- use no resistor.

- use transistors with higher current ratings.

Input Sensors and Actuators On-Vehicle

Vehicles Used: - 1991 Honda Integra XSI

- 1989 Nissan Skyline (R32) M-Spec

Battery Voltage to Injectors recorded was 14.1V

The voltage to the injectors is checked to see if the injectors have power to them.

If a lower voltage is found at the injectors than the battery then their may be high resistance in the circuit so the injectors would not have enough voltage to open.

Fuel injector circuit diagram

4.98V was recorded at the 5V reference wire. This reading is definitely acceptable.

The purpose of the reference voltage to the throttle position sensor is to see if the sensor has power to it.

Problems such as resistance in the wires and faulty circuit connections can affect the reference voltage, rendering the result incorrect.

Voltage reading at the TPS ground wire is 0.053V. A good ground will usually read less than 0.05V. This tells me that the ground at the TPS is in fact good.

This voltage tells me that the earth is good. This point is important to measure to make sure that their is not high voltage or resistance at earth

Problems such as bad connections, broken wires or a shorted circuit will result in a bad ground.

My reading from the Return/Output wire was 0.543V

With the throttle moved to the half open position my reading was 1.938V

As the throttle is moved to the WOT position the voltage increases to 4.11V

I was now asked to slowly open the throttle from the closed to open position. I observed on my multimeter that the voltage steadily increased with no sudden jumps or gaps in the signal. This observation tells me that the TPS Return/Output wire is OK.

The throttle position sensor (TPS) is used to inform the engine control module of accelerator pedal and throttle plate position. TP sensors are normally mounted on the throttle body with the throttle plate shaft running into the sensor. As the gas pedal is pushed, the throttle plate opens, rotating the sensors internal variable resistor. As the throttle opens, voltage returned to the computer from the Throttle Position Sensor varies (normally increasing), signaling the rate of throttle opening as well as throttle position. The computer uses this information to adjust fuel trim, which is the amount of time the injectors are open , delivering more fuel.

The types of sensor voltages that should be going go to the ECU as the throttle is opened and closed should be High voltage with the throttle open and low voltage with the throttle closed.

Problems which could occur to prevent the TPS from sending the correct voltage to the ECU could be bad connections, a break in the circuit or a shorted circuit.

Idle Wire: Colour: Teal

Volts at Idle: 12V

Volts at WOT: 12mV

Wide Open Throttle Wire: Colour: Green

Volts at Idle: 10mV

Volts at WOT: 12V

This output is needed for the ECU to properly run the engine because the ECU needs to know when to advance the timing as WOT is reached, and then to retard the timing when switched back to Idle or to suit driving conditions.

ECT supply wire was recorded at 3V

The engine was cold at this point of the test

For the temperature the vehicle was operating at this voltage seems to be correct.

Voltage at the ECT supply wire was only 2.6V after letting the engine warm up to optimum operating temperature.

A warmer engine should result in a lower voltage recorded . At cold I recorded 3V and at warm I recorded 2.6V. These readings show me that my previous statement is correct.

From the voltage signal of the ECT. the ECU knows what temperature the coolant is at. As the temperature of the sensor heats up, the voltage signal decreases. The decrease in the voltage signal is caused by the decrease in resistance. The change in resistance causes the voltage signal to drop. The ECT is connected in series with a fixed value resistor. The ECU provides 5 volts to the circuit and measures the change in voltage between the fixed value resistor and the temperature sensor. When the sensor is cold, the resistance of the sensor is high, and the voltage signal is high. As the sensor warms up, the resistance drops and voltage signal decreases. From the voltage signal the ECU can determine the temperature of the coolant. The ECU for this sensor is always at the ECU.

How does the ECT sensor voltage affect the fuel injection output from the ECU? If the ECT sensor voltage is high then this indicates that the car is cold. To warm up the car at a fast rate the injection spray time will be longer to get the car to optimum running temperature faster. The car will be running rich up until optimum running temperature is reached. After the car has reached this point the ECT will now be showing low voltage, meaning that the opposite will happen and the injection spray pattern time will decrease to make the car leaner.

Describe what could go wrong to create an incorrect voltage for the ECU? Faulty connections, a break in the wire, shorted circuit or a faulty ECT are all factors which can create an incorrect voltage for the ECU.

Recorded voltage was 0.007V. A good ground will usually read less than 0.05V.

This voltage tells me that the earth is good and it is important to measure this to check for high resistance or voltage at this point, which could result in a bad earth.

High resistance or voltage at the ground could make the earth bad.

Reading at Idle was 6.2V

Reading at 2500RPM was 9.6V

Reading at Idle now checking DC volts is 2.5mV

Reading in DC volts at 2500RPM was 3.5mV

Now reading Hz on your multimeter, I obtain a reading of 170Hz

Hz at 2500RPM was 550Hz

AC voltage definitely gave the best readings in order to know if the sensor is working correctly.

My engine has a magnetic CKP sensor, the sensor works using a iron cored coil with a magnet attached to one end. When a piece of ferrous metal is moved towards the end of the sensor it changes the shape of the magnetic field in the coil, this changing magnetic field then induces current to flow in the windings of the coil resulting in a small amount of electricity being generated.

This sensor only detects movement of ferrous objects near the sensor so is typically used for speed sensing (for example a wheel sensor in an ABS system) usually in combination with a toothed wheel.

They are very rugged sensors and are not affected by dirt and have a very high signal output making them less sensitive to noise (ideal for automotive applications).

On your multimeter their are different functions which will provide different readings, although AC voltage gives the best reading because the CKP sensor puts out AC voltage.

If the CKP sensor is faulty, their is a short in the circuit or a break in the wire then the ECU will not receive the correct signal from the CKP sensor.

MAP sensor input wire gave me a reading of 2.88V

Now I was to turn on the engine and let it idle.

I now received a reading of 0.880V

Next I gave the car a quick short acceleration and obtained a reading of 1.98V

The MAP sensor uses a perfect vacuum as a reference pressure. The difference in pressure between the vacuum pressure and intake manifold pressure changes the voltage signal the MAP sensor converts the manifold intake pressure into a voltage signal which tells the engine how much air is coming in.

The readings above show the basic principles of , with greater engine load results in more voltage output.

A faulty MAP sensor, break in the wire, bad connections or a shorted circuit will result in incorrect readings going to the ECU.

My recorded reading with the Key-on Engine-off was 3.1V

Next I started the engine, let it idle and got a reading of 1.3V

With a short sharp acceleration I received a reading of 2.1V

The Mass Air Flow sensor converts the amount of air drawn into the engine into a voltage signal. The ECU needs to know intake air volume to calculate engine load. This is necessary to determine how much fuel to inject, when to ignite the cylinder, and when to shift the transmission.

Readings to expect would be: -Low load driving conditions (Idle) = 1.3V

-Mid load driving conditions (Cruising) = 2.1V

-High load driving conditions (WOT) = 3.5V

The MAF readings above are within the manufacturers specifications.

A faulty MAF sensor, break in the wire, bad connection or shorted circuit will all result in the ECU not receiving the correct signal from the MAF sensor.

I obtained a reading of 1.93V, this result was less than my reading from the ECT when under going the same test. This shows that the IAT is hotter than the ECT due to the lower voltage reading recorded.

From the voltage signal of the IAT. the ECU knows what temperature the coolant is at. As the temperature of the sensor heats up, the voltage signal decreases. The decrease in the voltage signal is caused by the decrease in resistance. The change in resistance causes the voltage signal to drop. The IAT is connected in series with a fixed value resistor. The ECU provides 5 volts to the circuit and measures the change in voltage between the fixed value resistor and the temperature sensor. When the sensor is cold, the resistance of the sensor is high, and the voltage signal is high. As the sensor warms up, the resistance drops and voltage signal decreases. From the voltage signal the ECU can determine the temperature of the coolant. The ECU for this sensor is always at the ECU.

The ECU compares the ECT to IAT temperatures. If both temperatures are within 8° of each other, the ECU assumes that it is a cold start. Fuel injection will be increased and the car will run rich until the ECU obtains readings from the two sensors telling it that the car is now at optimum running temperature. If an incorrect signal was sent to the ECU then it may inject fuel when it is not needed. If the car was at optimum running temperature but the ECT or IAT send a voltage signal of 4.2V to the ECU, then the ECU will think that a cold start is needed and more fuel will be injected when it is not needed. This will cause the car to run very rich. The car will have more power, although will consume more petrol and may damage the internal workings of the engine.

The IAT signal should change dependant on different air temperature conditions. If the air temperature is low, then a high voltage signal (4.5V) and low resistance signal will be put out of the IAT. If the air temperature was hot then a low voltage (0.5V) and high resistance signal will be put out of the IAT.

A faulty IAT, break in the wire, bad connection or shorted circuit will all result in the ECU not receiving the correct signal from the IAT sensor.

- DC Volts: 34mV

- AC Volts: 1.3V

- Hz (Hertz): 32Hz

- Duty Cycle (%)